House# 02, Flat# 5A, Road# 11,Sector# 06

Uttara Model Town, Dhaka, 1230.

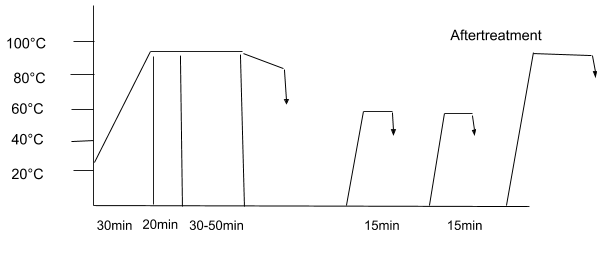

| Wetting Agent | 1-2g/L |

| Sequestering Agent | 1-2g/L |

| Leveling Agent | 0.5-1g/L |

| Direct Dyes | X% |

| Soda Ash | 1-5g/L |

| Glauber Salt | 5-20g/L |

| Temperature | 95±5°C |

| Time | 30-50 Mins |

| pH | Neutral to Alkaline |

| M:L | 1:5-1:10 |

| Lubricant | 1-3g/L |